Property demolition is never just about tearing down walls and hauling debris away. When older buildings are involved, especially those built before 1980, the real risk is often hidden inside insulation, flooring, roofing, and pipe wrap.

Asbestos remains one of the most heavily regulated and dangerous materials found on demolition sites, and failing to address it properly can lead to serious health consequences, project shutdowns, and significant legal penalties.

In states like Florida, New York, and California, regulatory oversight has only become stricter heading into 2026. Property owners, developers, and contractors are expected to complete thorough hazardous material assessments, follow EPA and OSHA protocols, and document every step of the abatement process before demolition begins. Cutting corners is no longer just risky, it is expensive.

Quick Answer: Proper asbestos removal during property demolition in Florida, as well as other regions such as New York and California, is essential to protect health, comply with regulations, and avoid costly legal penalties.

Licensed professionals must conduct thorough inspections and follow strict safety and disposal protocols before any demolition work begins. For official regulatory guidance, consult the U.S. Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA). Disclaimer: This guide is for informational purposes only and does not constitute legal or professional advice. Always consult qualified asbestos abatement professionals and regulatory authorities before beginning any demolition or hazardous material removal project.

Key Takeaways

- Asbestos must be identified and assessed before any demolition project to prevent health risks and legal violations.

- Always hire licensed professionals for asbestos removal to ensure compliance with regulations and safe handling procedures.

- Proper disposal of asbestos-containing materials is crucial; follow local and national laws to avoid fines or environmental hazards.

- Wearing appropriate personal protective equipment (PPE) is essential to minimize exposure during asbestos removal processes.

- Stay updated on changing asbestos-related regulations and best practices to ensure ongoing safety and compliance in future projects.

Types of Hazardous Materials Found in Demolition Sites

Demolition sites often contain a variety of hazardous materials that pose serious risks to workers, property owners, and nearby communities. Common substances include asbestos, lead, PCBs, mercury, mold, silica dust, and contaminated soil.

Identifying these materials before demolition is legally required and critical for safe operations. For more information on regulated hazardous materials, refer to the EPA Hazardous Waste Program. In states like Texas and Illinois, additional local regulations may apply to hazardous material management during demolition projects.

| Hazardous Material | Common Sources | Health Risks | Regulatory Requirements | Special Handling/Disposal |

|---|---|---|---|---|

| Asbestos | Insulation, floor/ceiling tiles, roofing, pipe wrap (pre-1980 buildings) | Mesothelioma, lung cancer, asbestosis | EPA NESHAP, OSHA, state/local laws | Licensed removal, double-bagging, disposal at approved facilities |

| Lead | Paint (pre-1978), pipes, solder | Neurological damage, developmental delays | EPA RRP Rule, OSHA | Certified abatement, hazardous waste disposal |

| PCBs | Electrical equipment, caulking, fluorescent light ballasts | Cancer, immune and reproductive system effects | TSCA, EPA | Specialized removal, incineration or secure landfill |

| Mercury | Thermostats, switches, fluorescent lamps | Neurological and kidney damage | EPA, state hazardous waste rules | Sealed containers, hazardous waste facility |

| Mold | Water-damaged materials, HVAC systems | Respiratory issues, allergic reactions | OSHA, CDC guidelines | Containment, HEPA filtration, safe disposal |

| Silica Dust | Concrete, masonry, stone cutting | Silicosis, lung cancer | OSHA Respirable Crystalline Silica Standard | Wet methods, respirators, dust control |

| Contaminated Soil | Underground tanks, industrial sites | Varies by contaminant (carcinogenic, toxic) | EPA, state environmental agencies | Excavation, testing, approved disposal |

Asbestos-Containing Materials by Building Age

Buildings constructed before 1980 carry the highest risk of asbestos-containing materials (ACMs). Asbestos was widely used in insulation, floor and ceiling tiles, roofing, and pipe wrap.

Visual identification is often unreliable, so certified testing is necessary to confirm the presence of asbestos before demolition begins.

Technical terms such as chrysotile, amosite, and crocidolite refer to the different types of asbestos fibers that may be present in building materials, each with unique health risks and abatement requirements.

Other Regulated Hazardous Substances

Lead-based paints are common in pre-1978 structures and require specialized testing and handling due to their toxicity. Polychlorinated biphenyls (PCBs) may be found in older electrical equipment and caulking products, requiring strict disposal procedures.

Mercury can exist in switches and thermostats, posing contamination risks. Additionally, mold growth and silica dust from concrete and masonry can cause respiratory hazards. Contaminated soil from underground storage tanks or previous industrial use also demands attention.

Failure to properly identify and manage these hazardous materials can result in significant fines, work stoppages, environmental cleanup costs, and serious health risks. For this reason, hiring licensed demolition professionals who conduct thorough hazardous material demolition assessments and follow EPA and OSHA guidelines is essential before any property demolition in Florida.

Disclaimer: Always seek guidance from certified professionals and local authorities to ensure all hazardous materials are properly managed and regulatory requirements are met.

Pre-Demolition Hazardous Material Assessment Requirements

Professional Inspection Process

Before demolition, an EPA NESHAP-compliant inspection must be performed by certified inspectors. This includes a detailed visual assessment of the building and surrounding areas, safe sample collection of suspected materials, and strict chain of custody procedures to maintain sample integrity.

These tests are sent to accredited laboratories for analysis to confirm asbestos or other hazardous substances. Analytical methods such as polarized light microscopy (PLM) and transmission electron microscopy (TEM) are commonly used to detect and quantify asbestos fibers in bulk and air samples.

Required Documentation and Permits

Once testing is complete, demolition contractors must prepare comprehensive asbestos survey reports and submit notifications to relevant state and federal agencies. Florida’s demolition permit requirements by county vary, so understanding local regulations is critical.

Proper permits and environmental site assessment services must be secured before work begins to ensure compliance and avoid project delays. For state-specific requirements, visit the Florida Department of Environmental Protection Asbestos Program.

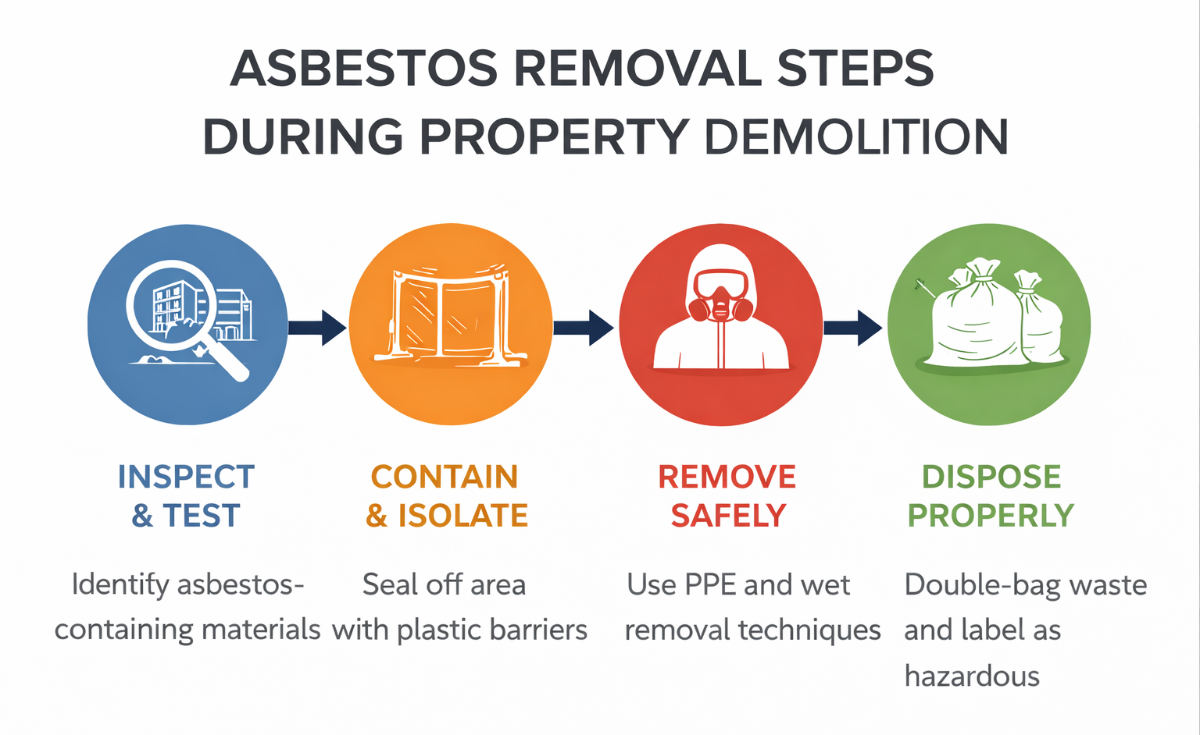

Safe Asbestos Removal Procedures for Demolition

Containment Setup and Work Area Preparation

Proper asbestos abatement starts with isolating the work area. Negative pressure systems prevent airborne fibers from escaping, while thick plastic sheeting seals off the demolition zone. Controlled entry and exit points help maintain containment and reduce contamination risks.

Glove bags and mini-enclosures may be used for localized abatement of asbestos-containing materials such as thermal system insulation or pipe lagging.

Worker Safety and PPE Requirements

Workers must wear properly fitted respirators, protective clothing, gloves, and eye protection. Respirator fit testing and medical surveillance programs ensure personnel are safe throughout the removal process. Wet removal techniques suppress fiber release by keeping asbestos materials damp during handling.

Continuous air monitoring verifies that airborne asbestos levels remain below regulatory limits. After removal, thorough decontamination stations reduce cross-contamination risks. The use of HEPA-filtered vacuums and negative air machines is standard practice to capture airborne asbestos fibers during abatement activities.

Legal Compliance and Regulatory Requirements

Demolition projects involving hazardous materials like asbestos are regulated by federal, state, and local laws to protect workers and the public. The EPA’s NESHAP regulations mandate thorough inspection, notification, and safe removal procedures before demolition. OSHA enforces worker protection standards including PPE use and training.

Federal Regulations and Enforcement

In 2026, EPA enforcement actions have increased, with a growing number of citation cases for improper asbestos handling. OSHA continues to issue citations for inadequate worker safety protocols. Criminal liability is possible in severe violation cases. Maintaining compliance avoids costly stop-work orders and legal penalties.

State and Local Compliance Variations

Florida requires demolition contractors to hold specific licenses for asbestos abatement, with additional local notification and permit requirements. These vary by county and municipality, making it essential to consult resources like the Demolition Permit Hillsborough County guidelines. Municipal inspections and record-keeping obligations help ensure regulatory adherence throughout the project. For more details, see the Florida Department of Environmental Protection.

Working with licensed, insured demolition contractors familiar with these regulations is key to avoiding compliance issues and ensuring safe project completion.

Health Risks and Long-Term Exposure Consequences

Exposure to asbestos fibers during demolition can cause serious diseases such as mesothelioma and lung cancer. These illnesses often have long latency periods, sometimes developing decades after exposure.

Secondary exposure can affect family members of workers through contaminated clothing and equipment. The inhalation of friable asbestos, which easily crumbles and releases fibers, poses the greatest health risk during demolition activities.

Failure to manage asbestos hazards properly creates liability risks for property owners and contractors, including medical monitoring obligations and potential lawsuits. Understanding these long-term health consequences highlights why strict asbestos abatement protocols are essential.

Proper Disposal and Transportation Methods

Waste Classification and Packaging

Asbestos waste must be classified according to EPA’s Resource Conservation and Recovery Act (RCRA) hazardous waste categories. Double-bagging with labeled, leak-tight containers is required to prevent fiber release during transport.

Containers must meet specific durability and sealing standards. In some jurisdictions, such as California, additional labeling and manifesting requirements may apply for the transportation of regulated asbestos-containing material (RACM).

Waste must be transported using approved manifests that track disposal from the demolition site to EPA-approved facilities.

This ensures accountability and environmental safety. Although proper disposal adds to project costs, non-compliance leads to hefty fines and environmental damage.

Cost Factors and Project Planning Considerations

Asbestos removal costs vary widely, often calculated per square foot of affected material. Factors influencing price include building size, material type, accessibility, and disposal requirements. Scheduling the removal phase early in the project timeline prevents delays.

Insurance and bonding are mandatory for contractors handling asbestos, adding to project expenses but protecting all parties involved. Comparing the cost of full compliance with potential penalties clearly favors professional asbestos abatement for demolition projects.

Fast, reliable demolition services from licensed pros with decades of field experience.

Frequently Asked Questions

How long does asbestos removal take before demolition can begin?

Asbestos removal typically takes 1-4 weeks depending on the size and complexity of the building. Weather conditions and site accessibility can impact timelines. Permit processing and required notifications may also extend the schedule.

Can demolition contractors perform their own asbestos removal?

Only contractors with separate EPA and Florida state asbestos abatement licensing can legally perform removal. They must meet different insurance and bonding requirements and possess specialized equipment and training to comply with safety standards.

What happens if asbestos is discovered during demolition?

Work must stop immediately to prevent exposure. Emergency abatement procedures are implemented, including containment and specialized removal. Discovering asbestos mid-demolition can result in EPA violations and costly fines if not properly managed.

Are there alternatives to full asbestos removal for demolition?

Encapsulation methods are generally unsuitable for demolition projects since the structure is being removed completely. Wet demolition techniques may reduce fiber release in minor contamination cases, but total asbestos abatement is usually required.

How do I verify an asbestos removal contractor is properly licensed?

Check state environmental agency databases and EPA certification lists. Confirm the contractor holds current insurance and bonding. Request copies of license documentation and certifications before hiring.

Get Your Free Demolition Quote

For safe and compliant property demolition asbestos removal in Florida, professional assessment and licensed removal services are essential. Protect your property, workers, and community by planning carefully and meeting all regulatory requirements.

Disclaimer: Always consult with licensed asbestos abatement professionals and local regulatory agencies before starting any demolition project to ensure full compliance and safety.

Contact us today to start your project with confidence and compliance.